From your project to the finished product

Quality and certifications of ICOS di Leonelli Marino spa

At ICOS di Leonelli Marino SpA Lavorazione Lamiere, we hold all the necessary certifications for metalworking. In particular, as far as quality system management is concerned, our company in Zola Predosa can display UNI EN ISO 9001:2015 certification. The experience and training of our staff, together with the use of cutting-edge production technologies and meticulously organised work processes, allow us to manufacture products that fully comply with the reference standards. Our staff is always available to illustrate the various project possibilities and to define the specifications: contact us if you would like to take advantage of our services or if you would like to learn more about the certifications we hold in relation to metalworking.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Quality management system

9001:2015 certified since 1998

ICOS is a leading company in the field of contract metalworking. Among the processes carried out by our company are, in particular

CNC sheet metal bending;

- laser cutting of sheet metal with automatic magazines;

- 3D laser cutting;

- robotic welding and spot welding;

- sheet metal stamping;

- sheet metal deep-drawing;

- construction of moulds and equipment;

- mechanical machining.

We have quality certifications for all the processes to which we subject metals.

Obtaining new welding certification according to ISO 3834 - 4:2021

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

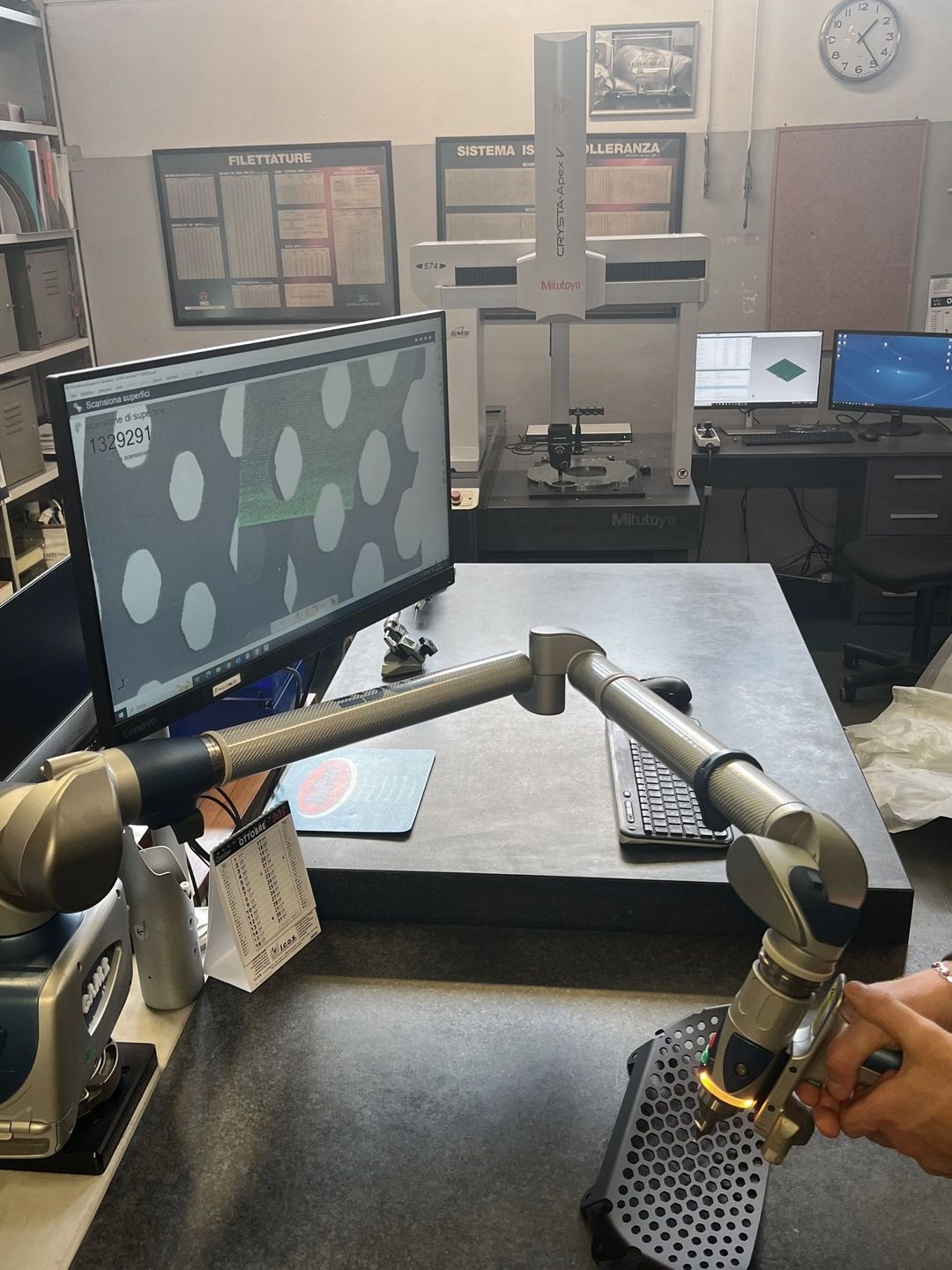

Metrology room

The members of our team are always ready to provide ad hoc consultancy aimed at identifying the best design solutions and carrying out large and medium series production according to drawing.

Our testing department also verifies the conformity of manufactured parts in accordance with UNI EN ISO 9001:2015 quality certifications (Cermet Accredia since 1998, registration no. 624 - A).

The aforementioned department relies on the technology of the metrology room, which uses a three-dimensional Mitutoyo machine as its primary instrument.The testing instruments we use are as follows:

- gauges 1/100 from 150 to 1000 millimetres and micrometers for outdoors 1/100 and 1/1000, for indoors 1/100;

- altimeters up to 600 millimetres

- roughness tester

- hardness tester;

- thickness gauges;

- threaded plug gauges;

- laser scanning measuring arm.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

LOCATION

Via Curiel 4

40069 Zola Predosa (BO)

OPENING HOURS

- Mon - Fri

- - -

- Sat - Sun

- Closed

Vat No. 00523911204 Legal information

|

Privacy Policy and Cookie Policy