From your project to the finished product

Mould construction and maintenance equipment in Bologna

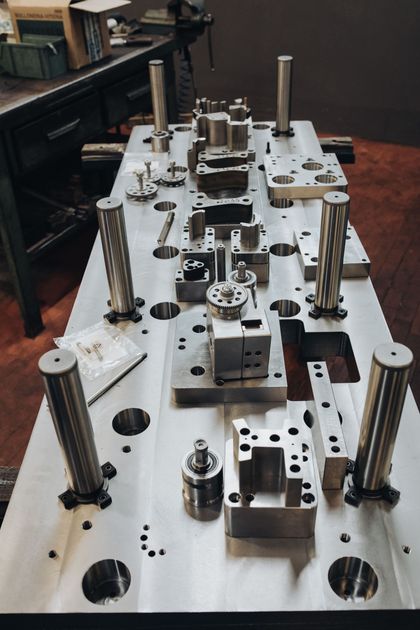

The in-house tooling shop is a fundamental service for satisfying new projects that customers may request from us. From the drawing of the part, we are able to design the mould for the production of the parts, which will then be realised in the adjacent Moulding Department.

In addition, the strength of the tooling is determined by the possibility of intervening during production in the event of breakages or modifications requested by the customer; this allows us not to suffer production stoppages and not to stop the production cycle.

Slide title

Write your caption hereButton

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Moulds, stamping and deep-drawing machines

for sheet metal deformation

Thanks to sophisticated 3D design software and advanced CAD-CAM technologies, our engineering department is able to develop particularly sophisticated simulations, prototypes, products and components for tooling and moulds.

We manufacture tooling for stamping, progressive dies, forming and deep-drawing of metals, and we take a close look at all stages from planning to maintenance of the tools during the production cycle.

We intervene to overhaul or modify the mould of the part in production.

We guarantee timely intervention if necessary on the moulds being processed in the adjacent moulding department. We also make spare parts for high-production tools to avoid insidious production stoppages.

The Equipment Service is able to support the customer in Research and Development for the realisation of new projects: call or write for more information

LOCATION

Via Curiel 4

40069 Zola Predosa (BO)

OPENING HOURS

- Mon - Fri

- - -

- Sat - Sun

- Closed

Vat No. 00523911204 Legal information

|

Privacy Policy and Cookie Policy